The Buzz on Motorcycle Parts New Zealand Specialists

Table of ContentsSome Known Details About Motorcycle Parts New Zealand Specialists Excitement About Motorcycle Parts New Zealand Specialists10 Simple Techniques For Motorcycle Parts New Zealand SpecialistsFacts About Motorcycle Parts New Zealand Specialists RevealedThe 4-Minute Rule for Motorcycle Parts New Zealand Specialists8 Easy Facts About Motorcycle Parts New Zealand Specialists DescribedThe Buzz on Motorcycle Parts New Zealand SpecialistsThe Only Guide to Motorcycle Parts New Zealand Specialists

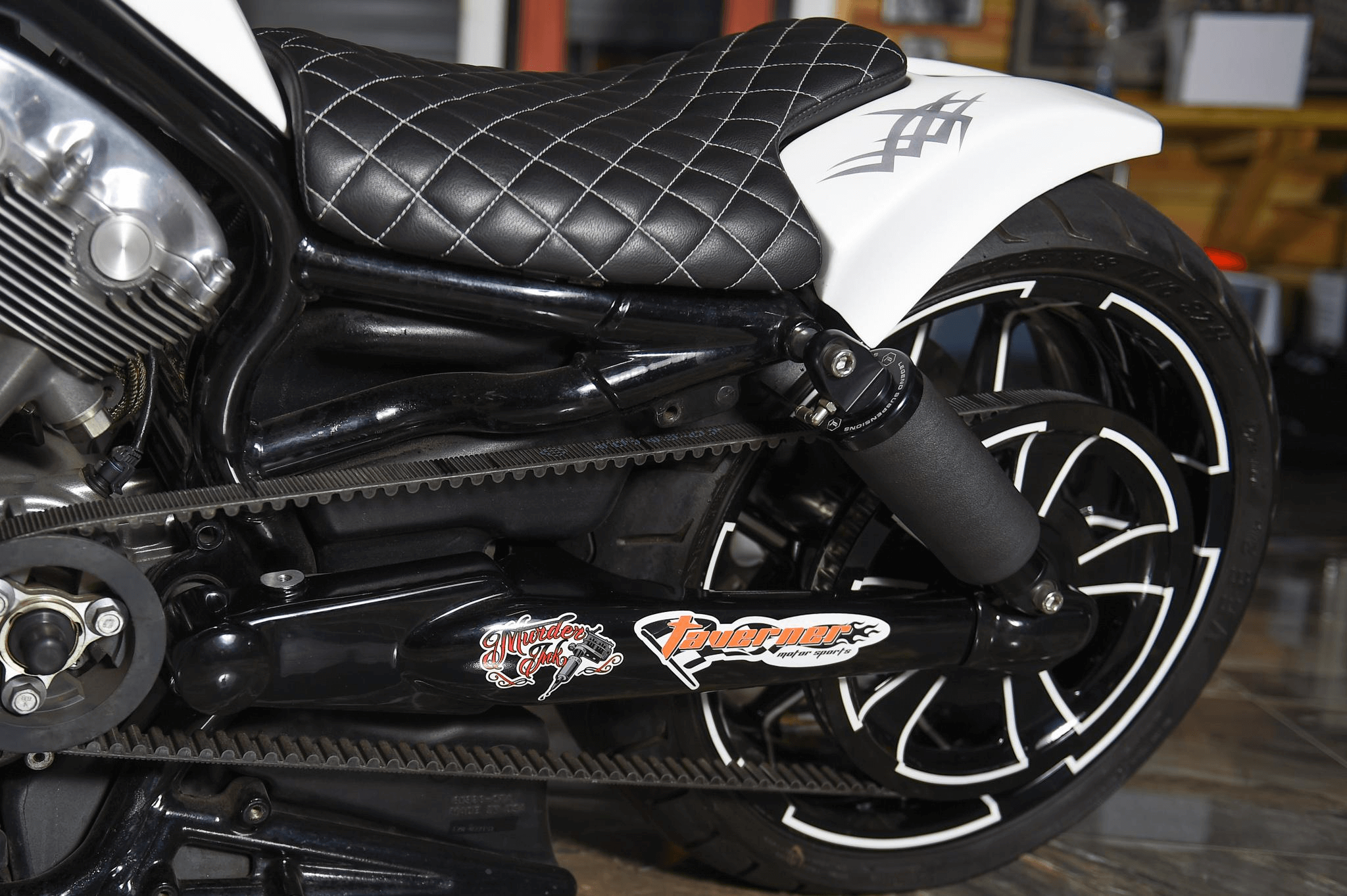

Reach out to one of our specialists today.CNC machining innovation is quickly coming to be the prime focus of various production procedures around the world as a direct result of its numerous advantages over other approaches. In addition, the industries that produce bikes have obtained on board with this fad. One of the most innovative business are currently establishing their engine parts and wheels utilizing machining strategies originally established for motorcycle parts.

You may be questioning why we utilize. Now that we have your focus allow us describe the rationale behind this modern development in the bike manufacturing industry.

The Best Strategy To Use For Motorcycle Parts New Zealand Specialists

In addition, you have full control over the appearance of the components, also down to the minute information. Sometimes, motorcyclists might determine to spruce up their experience by setting up aftermarket elements or changing the bike's makeover.

Fascination About Motorcycle Parts New Zealand Specialists

CNC machining might be used to make almost all of a motorcycle's steel and plastic parts. To proceed, we'll discuss numerous machined components for motorcycles.

When customizing the wheels, the disks are where the focus should be. Most of them are constructed out of aluminum. Light weight aluminum alloys are widely known for the superior machining capabilities that they have. Milling treatments are utilized to obtain the preferred degree of wheel customization. An additional facet of the motorbike that might be personalized is the tires.

The smart Trick of Motorcycle Parts New Zealand Specialists That Nobody is Discussing

When it concerns a vehicle (or a motorcycle), one of the most crucial part is the engine. A number of individuals point to it as the "heart" of the automobile. On the various other hand, the camshaft, the cylinder head, and the pistons often tend to be intricate and require layouts with a high level of accuracy.

Illumination is another facility element of customization. Usage just premium things, nonetheless, since these lights are important for the safety and security of motorcyclists and other vehicle drivers or people on the roadway, especially during the night. Bike fronts lights have three major components: the bulb, or source of light, the lens, and the real estate. In particular, we tailor the lens and the real estate.

Milling procedures with a remarkable finish would cause the lenses having a reflective top quality that is comparable to that of a mirror. The cover, on the other hand, is not composed of delicate materials; instead, it is built out of tough polymers that can be machined right into even more complex patterns.

Get This Report about Motorcycle Parts New Zealand Specialists

Bike suppliers commonly cast these components, yet only for the production of bespoke parts. Machining on 5 axes in today's globe is the methods by which any layout shape might be recognized.

Select Runsom for your tailored motorbike components! We have the capacity to produce complex and fashionable elements making your bike incomparable.

Here are a few examples of steels often utilized in bike component machining. Aluminum is the main product made use of by firms focusing on generating personalized motorcycle elements to produce most of these parts. In the past, we would build our engines out of cast iron. On the other hand, light weight aluminum is swiftly coming to be the product of choice, partly due to the fact that it is a lot more light-weight.

Zinc describes an additional steel that is extremely light in weight and has great machining qualities due to its high mechanical strength. This material might be created right into nearly any type of shape and preserves its dimensions well. Also mission-critical parts that require a high degree of accuracy may profit from their usage.

See This Report on Motorcycle Parts New Zealand Specialists

Another steel that sees hefty usage in the manufacturing of CNC-customized elements is magnesium. It is amongst the lightest metals that are currently obtainable and has excellent machinability Visit This Link functions and strength proportionate with its reduced weight. One of the disadvantages of magnesium is that its dirt may quickly capture fire.

Due to its remarkable machinability and weldability, stainless-steel is an alloy that is particularly well-suited for CNC processes. They have terrific rust resistance and a high aesthetic appeal. Their most typical usage in creating various motorbike elements is fasteners, such as screws and screws. Their low susceptibility to oxidation and corrosion makes them ideal for this use.

Motorcycle Parts New Zealand Specialists Fundamentals Explained

It seems that CNC turning and crushing are the foundational procedures. In enhancement, it requires keeping bars of product, most often plastic or steel, in position and then turning a cutting device to get rid of sections of the material as the product is transformed.

These techniques are just as important and produce components with high accuracy and constant top quality. They are respectively: grinding, laser cutting, and drilling. The term "surface coating" describes post-processes after the preliminary machining phase. Motorcycle Parts New Zealand Specialists. visit here The procedures assist boost the overall high quality of the machined bike parts. Below are the short introduction, pros and cons of five surface treatment techniques.

The Buzz on Motorcycle Parts New Zealand Specialists